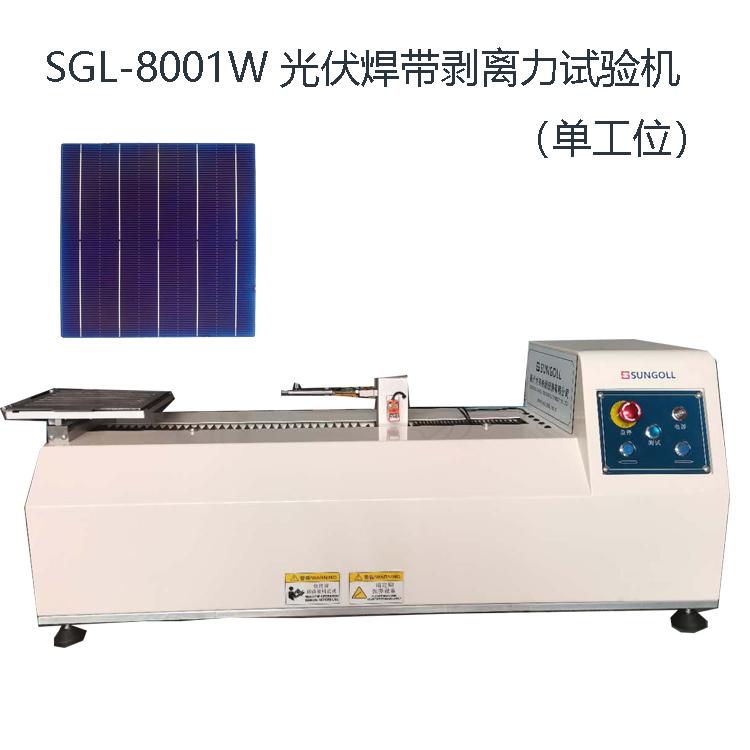

Tensile testing machine for welding strip of photovoltaic cells

Model No.︰SGL-8001W

Brand Name︰SUNGOLL

Country of Origin︰China

Unit Price︰CNY ¥ 28000 / pc

Minimum Order︰1 pc

Product Description

Name: computerized photovoltaic welding strip peeling force testing machine (Welding Strip Tensile testing machine)

Model: sgl-8001w; sgl-8009w; sgl-8012w

Brand: sungoll / Shanggao detection

Product introduction:

Horizontal special testing machine for photovoltaic cell peeling force is specialized for photovoltaic cell industry. It can stretch and peel multiple welding strips at the same time, which greatly reduces the labor cost. Can customize 5-channel, 6-channel, 9-channel, 12-channel photovoltaic peel strength testing machine. The stripping force tester for photovoltaic welding tape is a special instrument specially developed by our company for testing the stripping force, tensile strength and other parameters of silicon materials, silicon wafers, cells, battery modules and other products in the photovoltaic industry. However, corresponding tools and machine forms should be equipped for different parameter tests. The instrument software development has integrated all the above test requirements;

Product advantages:

1. It has wide and accurate loading speed and measuring force range, and has high precision and sensitivity for load, deformation and displacement measurement and control.

The unique horizontal design is adopted, which has the characteristics of compact structure, complete functions and convenient operation; it fully meets the requirements of national standard GB / T 12914-91 (constant speed drawing method). The design also refers to the national and industrial standards such as GB 13022-91, GB / t1040-92, gb2792-81, GB / t14344-9, GB / t2191-95, QB / t2171-95 and other national and industrial standards.

This quotation model is a sensor, the testing machine can be installed with five force sensors, with high-tech intelligent software, six sensors can be used at the same time, and the test data can be displayed on the computer software at the same time, operation error free, easy to use.

This testing machine is specially used for 180 degree peeling strength test of solar cells in solar industry. The horizontal structure saves space and is easy to operate. The simultaneous stretching of working position can reduce manual operation and save test time. It can also test one or two working positions only. The data is not affected and the accuracy is guaranteed.

5. This machine adopts computer control, professional test program for data analysis and processing, combined with high-resolution force acquisition sensor and high-precision data processing chip, presents the intuitive performance curve of customers and the data value after processing required by customers, so as to understand the product performance more intuitively and accurately, so as to improve the product quality.

Technical parameters:

The capacity of the instrument can be selected as 50N, 100N, 200N, 500N (optional), and the standard configuration is 200N;

Instrument operation mode: full computer special app program operation;

Instrument force resolution: 1 / 500000;

The force accuracy of the instrument is ± 0.1% (1-100% FS) of the indicated value;

Test space: stretching stroke is about 500mm, which can be customized according to customer's product requirements;

The displacement velocity measured by the instrument is 0.1-500mm/min;

Displacement resolution: 0.001mm;

The fixture of the instrument can be moved left and right with the size of 0 ~ 160mm, with quick locking device;

Instrument unit switching: GF, KGF, N, LBF, etc;

Instrument drive system: servo motor + driver set;

Instrument transmission system: ball screw imported from Taiwan Shangyin;

Machine size: about 1200 * 350 * 490mm;

Weight: About 50kg

Instrument power supply: φ 2, 220 V / 50 Hz, 5 A;

Features:

1. Advanced chip integration technology, professional design of data acquisition and amplification system, with high integration, stable and reliable, easy to use and other advantages. The control software can automatically calculate the tensile strength, breaking strength, peel strength, elongation and other test data, and the open formula editing can automatically calculate the data results of the force, stress, displacement and deformation of any specified point in the test process. The control and data processing of the test process meet the requirements of the corresponding national standards for metallic and non-metallic materials.

2. Control mode: fixed speed, fixed displacement, fixed load and other control modes are optional;

3. Automatic reset: after the test starts, the measurement system automatically adjusts to zero;

4. Automatic shift: automatically switch to the appropriate range according to the load to ensure the accuracy of measurement data;

5. To prevent the test data from being lost automatically;

6. Batch test: for samples with the same parameters, one batch of tests can be completed in sequence after one setting;

7. Display mode: data and curve are displayed dynamically with the test process;

8. Curve traversal: after the test is completed, the curve can be re analyzed, and the corresponding data of each point on the test curve can be found with the mouse;

9. Curve selection: stress-strain, force displacement, force time and displacement time curves can be selected for display and printing;

10. Unit switching: force unit: (g, kg, N, LB), stress unit: (kg / mm2, N / mm2, MPa, LBF / in2) displacement unit: (m, mm, in)

11. Test report: the test report can be programmed and printed according to the format required by users, and can be exported to excel file;

12. Safety protection: when it exceeds 2-10% of the maximum load, it can automatically realize the safety protection;

13. It can automatically detect and calculate the mechanical property index of the sample, and also can manually intervene the analysis process. According to the requirements of relevant standards, the automatic analysis results can be modified to improve the accuracy of the data;

14. Body: high quality aluminum profile and high-grade paint special treatment, beautiful and durable, no discoloration, no decolorization.

Payment Terms︰ TT

Product Image